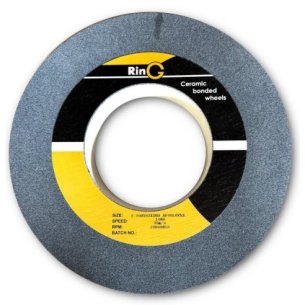

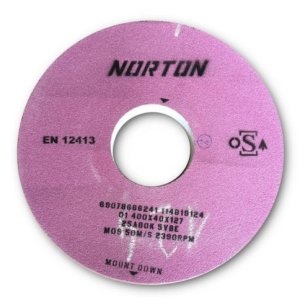

Grinding Wheel on Ceramic Bond 300x40x127 GC F46L 6VS3

This grinding wheel is a specialized tool created for working with materials that require a specific approach due to their hardness, brittleness, or sensitivity to heat. Made from green silicon carbide (GC), it is the ideal choice for processing cast iron, ceramics, glass, stone, non-ferrous metals, and hard alloys. Thanks to its optimal characteristics, the wheel guarantees a clean and precise grind without the risk of damaging the workpiece.

Key Advantages and Features:

- Specialized Abrasive (GC): Silicon carbide is harder and sharper than aluminum oxide, making it indispensable for cutting ultra-hard materials.

- High Cutting Ability and "Cool" Grinding: The soft hardness (L) and moderately porous structure (6) ensure continuous renewal of cutting grains and effective heat dissipation, preventing burning.

- Precision for Brittle Materials: The wheel is perfectly suited for processing brittle materials, minimizing the risk of chipping and cracking.

- Form Stability: The ceramic bond ensures that the wheel will maintain its precise shape throughout its service life, which is critical for high-precision operations.

Technical Specifications and Application:

- Type: Flat grinding wheel (Type 01).

- External Diameter (D): 300 mm.

- Thickness (H): 40 mm.

- Bore Diameter (d): 127 mm.

- Abrasive Material: GC (Green Silicon Carbide).

- Grit: F46 (medium).

- Hardness: L (Soft).

- Structure: 6 (moderately porous).

- Bond: Ceramic (VS3).

- Purpose: Processing hard, brittle, and non-metallic materials.

- Application: Cylindrical and surface grinding machines in manufacturing and repair shops.