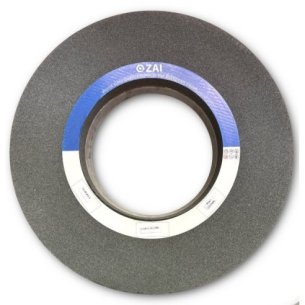

Grinding Wheel on Ceramic Bond 64C 600x63x305 F60 J 35

This large-sized grinding wheel is a highly specialized tool designed for working with materials that are too hard or brittle for standard abrasives. Made from green silicon carbide (64C), known for its exceptional hardness and sharpness, the wheel provides high performance when processing hard alloys, cast iron, ceramics, and glass. Its design is intended for use on industrial grinding machines, common in the machine building and aviation industries.

Key Advantages and Features:

- Specialized Abrasive (64C): Green silicon carbide is harder than aluminum oxide, making it ideal for cutting and grinding ultra-hard, non-metallic materials and tungsten-based alloys.

- Efficient Heat Dissipation: The open structure (35) ensures easy swarf removal and effective heat dissipation, preventing overheating and damage to sensitive workpieces.

- Clean Grind: The optimal combination of grit (F60) and medium-soft hardness (J) allows for a clean, even surface after grinding with no deep scratches or burning.

- High Wear Resistance: The properties of silicon carbide and the strength of the ceramic bond ensure a long service life, even under intensive use.

Technical Specifications and Application:

- Type: Flat grinding wheel (Type 1).

- External Diameter (D): 600 mm.

- Thickness (H): 63 mm.

- Bore Diameter (d): 305 mm.

- Abrasive Material: 64C (Green Silicon Carbide).

- Grit: F60 (medium).

- Hardness: J (medium-soft).

- Structure: 35 (open).

- Bond: Ceramic.

- Purpose: Grinding of hard and brittle materials, hard alloys.