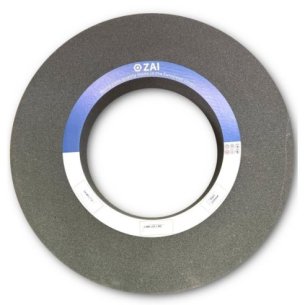

Grinding Wheel on Ceramic Bond 200x13x32 8A 60 L 7 V

This grinding wheel is a specialized tool created for performing precision tasks in fine grinding and sharpening. Its unique double-beveled profile (Type 3) allows for highly accurate work with complex geometries, making it indispensable in the manufacturing and maintenance of cutting tools like milling cutters, lathe tools, and drills. The combination of high-quality abrasive and a ceramic bond guarantees excellent results.

Key Advantages and Features:

- High Precision and Clean Grind: Thanks to its shape and optimal characteristics, the wheel ensures precise grinding and a clean surface without deep scratches, which is critical for the quality of cutting tools.

- Minimal Wear: The soft hardness (L) combined with a porous structure (7) provides a self-sharpening effect, extending the wheel's service life and reducing wear.

- Resistance to Thermal Loads: The porous structure effectively dissipates heat, preventing overheating and burning of the tool, which preserves its strength and cutting properties.

- Stable Form: The rigid ceramic bond ensures that the wheel's geometry is maintained during operation, which is the key to a stable and accurate result.

Technical Specifications and Application:

- Type: Double-beveled (Type 3).

- External Diameter (D): 200 mm.

- Thickness (H): 13 mm.

- Bore Diameter (d): 32 mm.

- Abrasive Material: 8A (White Fused Aluminum Oxide).

- Grit: 60 (medium).

- Hardness: L (Soft).

- Structure: 7 (Porous).

- Bond: Ceramic (V).

- Purpose: Fine grinding and tool sharpening.

- Application: Micromechanics, sharpening of milling cutters, lathe tools, drills, and other tools.