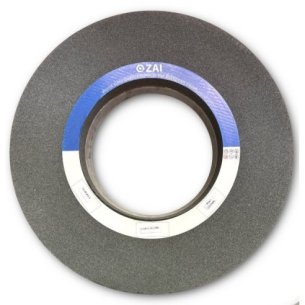

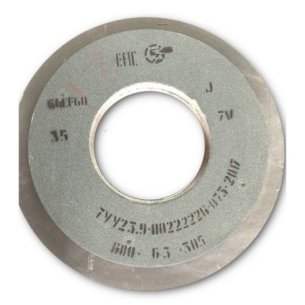

Grinding Wheel on Ceramic Bond 150x10x32 8A 40 K/L 6 V

This grinding wheel is a specialized tool designed for precision work that cannot be performed with standard flat wheels. Its double-beveled profile (Type 3) allows for processing complex contours and profiles, which is crucial for manufacturing and sharpening cutting tools, as well as parts with intricate shapes. The ceramic bond guarantees stability and accuracy throughout its service life.

Key Advantages and Features:

- High Profile Accuracy: The specific shape of the wheel allows for exceptional precision when processing angles and profiles, which is indispensable in tool manufacturing.

- Stable Form During Operation: The rigid ceramic bond ensures that the wheel's geometry is maintained, even under high load, guaranteeing a high-quality and consistent result.

- Low Vibration: The optimal structure and balancing of the wheel minimize vibrations, leading to an improved surface finish and reduced operator fatigue.

- Clean Processing: The 8A abrasive combined with the soft K/L hardness and porous structure 6 ensures effective heat dissipation, preventing burning and changes in the metal's properties.

Technical Specifications and Application:

- Type: Double-beveled (Type 3).

- External Diameter (D): 150 mm.

- Width (H): 10 mm.

- Bore Diameter (d): 32 mm.

- Abrasive Material: 8A (Fused Aluminum Oxide).

- Grit: 40 (medium).

- Hardness: K/L (soft/medium-soft).

- Structure: 6 (moderately porous).

- Bond: Ceramic (V).

- Application: Tool shops, machine tool building, processing of complex shaped parts.