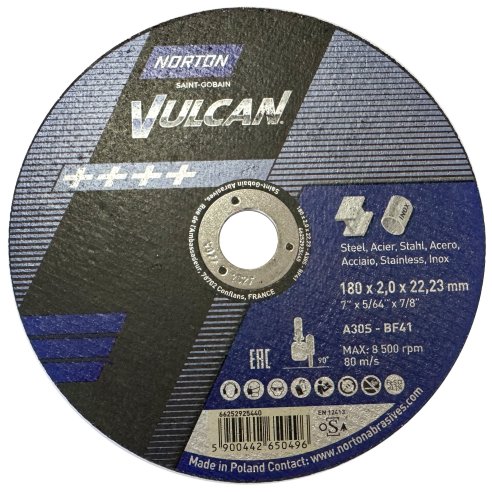

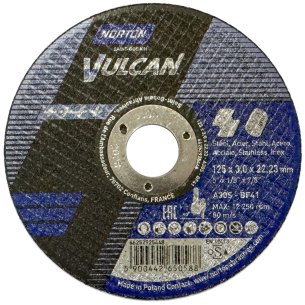

NOR T41-180x2.0x22.2- A30S- BF VULCA Cutting Disc: The Optimal Choice for Metal

Introducing the **NOR T41-180x2.0x22.2- A30S- BF VULCA reinforced abrasive cutting disc with a phenolic resin bond**. This disc is a high-performance tool, specifically designed for efficient and fast cutting of various types of metal. Its optimal thickness of 2.0 mm combined with a diameter of 180 mm makes it a versatile solution for a wide range of tasks.

High Performance and Versatility

The NOR VULCA disc with A30S grit is intended for aggressive yet controlled cutting. It excels at working with:

- Structural Steel: Ensures fast and clean cuts of metal profiles, pipes, and sheets.

- Stainless Steel (Inox): While not strictly "iron-free" (like some Inox-specific discs), it is effective for general Inox cutting where contamination is a less critical factor.

- Other Ferrous Metals: Effective for working with cast iron and other metal alloys.

Key Features and Benefits:

- Efficient Cutting: The A30S grit (medium coarseness) provides aggressive material removal and fast cutting.

- Durability and Strength: The high-quality phenolic resin bond ensures strong retention of abrasive grains and a long service life for the disc.

- Enhanced Safety: BF (Reinforced) type reinforcement provides additional strength and resistance to disc breakage, making work safer. Type 41 (T41) indicates a flat disc shape, which is standard for cutting applications.

- Operational Stability: Thanks to its design, the disc provides stable and controlled cuts, minimizing vibrations.

- Versatile Application: Ideal for use with angle grinders for various metalworking tasks.

Technical Specifications:

- Disc Type: Cutting, reinforced (Type 41 / T41).

- Diameter: 180 mm.

- Thickness: 2.0 mm.

- Bore Diameter: 22.2 mm.

- Grit Size: A30S (electro-corundum, medium-coarse grit).

- Bonding: Phenolic resin with BF reinforcement.

- Intended Use: For metal cutting.

By choosing the NOR T41-180x2.0x22.2- A30S- BF VULCA disc, you gain a reliable and efficient tool that will ensure high-quality execution of your metalworking tasks.